In today's hyperconnected business environment, organizations generate and consume knowledge at unprecedented rates. Yet research shows that knowledge workers spend an average of 2.5 hours daily searching for information, with 90% of organizational knowledge remaining trapped in silos or simply undiscoverable. This knowledge chaos costs businesses far more than just time—it undermines decision-making, stifles innovation, and creates competitive disadvantages that compound over time.

What if there was a proven methodology to bring systematic order to organizational knowledge? Enter 5S Knowledge Management—a revolutionary adaptation of the time-tested manufacturing methodology that transforms how organizations capture, organize, and leverage their intellectual assets.

This article introduces a comprehensive framework that applies the five S principles (Seiri, Seiton, Seiso, Seiketsu, Shitsuke) to knowledge management, creating systematic approaches that deliver measurable results. You'll discover how to eliminate knowledge waste, optimize information flows, and build sustainable knowledge practices that drive organizational excellence.

The evidence is compelling: organizations implementing systematic knowledge management approaches report 25-60% productivity improvements, 73% gains in overall efficiency, and ROI within six months. More importantly, they build resilient knowledge ecosystems that adapt and improve continuously.

Understanding the Convergence: 5S Methodology Meets Knowledge Management

The 5S Foundation: More Than Workplace Organization

The 5S methodology originated in Japan as part of the Toyota Production System, representing five Japanese terms that create systematic workplace excellence. 5S has demonstrated remarkable versatility across industries, from healthcare centers achieving 32% capacity increases without construction to service organizations reducing operational time by 8-18%.

The Five S Principles:

- Seiri (Sort): Separate necessary from unnecessary items

- Seiton (Set in Order): Organize everything systematically

- Seiso (Shine): Clean and maintain the organized system

- Seiketsu (Standardize): Create consistent procedures

- Shitsuke (Sustain): Develop discipline for continuous improvement

Why Traditional Knowledge Management Falls Short

Traditional knowledge management approaches often focus primarily on technology solutions or rely on unstructured sharing initiatives. Research demonstrates that "in SMEs, there is an absence of systematic knowledge management" (Dabic et al., 2020, p. 2), leading to significant challenges including:

- Information fragmentation across multiple systems

- Inconsistent quality of captured knowledge – empirical evidence shows that "knowledge management practices were measured by asking the respondents to answer a set of items on a scale from 1 to 7" with significant variations in implementation quality (Kianto et al., 2016, p. 9)

- Lack of systematic maintenance leading to outdated information

- Absence of sustainable practices for knowledge organization – studies reveal that "only few SMEs think of Knowledge Management as a strategic asset, the others simply execute it to meet compliance" (Fehlau, 2025)

The 5S-KM Convergence Opportunity

The convergence of 5S methodology with knowledge management creates unprecedented opportunities for systematic knowledge excellence. Research demonstrates that "systematic knowledge management practices act as the underlying mechanisms that explain the effect of absorptive capacity on firms' innovation-related performance" (Dabic et al., 2020, p. 3). Organizations implementing comprehensive, structured approaches to knowledge management achieve 58% success rates compared to 26-30% for ad-hoc initiatives.

This systematic approach aligns perfectly with modern quality management requirements. Empirical evidence confirms that "transformational leadership, strategy, and information technology constitute the foundation of a supportive workplace that improves the effectiveness of knowledge management" (Sayyadi, 2019, p. 6). The integration of systematic 5S principles provides the structural foundation for this transformational approach.

Implementing 5S Knowledge Management: A Systematic Framework

Seiri-Knowledge (Sort): Systematic Knowledge Curation

Principle: Distinguish essential knowledge from information clutter and eliminate knowledge waste systematically.

Implementation Framework:

1. Knowledge Asset Assessment Begin with comprehensive knowledge auditing using quantitative criteria:

- Relevance scoring: Rate information usefulness on 1-5 scale

- Usage analytics: Track access frequency over 6-month periods

- Currency evaluation: Identify content older than 18 months for review

- Quality assessment: User ratings and expert validation scores

2. Knowledge Elimination Protocols Establish systematic criteria for knowledge disposal:

- Information unused for 12+ months without strategic value

- Duplicate content with inferior quality or completeness

- Outdated procedures superseded by newer versions

- Content failing quality standards after remediation attempts

Thought Experiment – Manufacturing SME Knowledge Audit: Consider a hypothetical precision manufacturing company with 75 employees facing critical knowledge transfer challenges as experienced machinists approach retirement. Implementing Seiri-Knowledge principles would involve systematically cataloging all technical documentation, identifying which machining procedures remain current versus obsolete, and prioritizing knowledge capture from departing experts. Expected outcomes, based on established 5S principles, would include 40-60% reduction in document volume while improving access to truly essential information.

Seiton-Knowledge (Set in Order): Systematic Information Architecture

Principle: Create logical, efficient organization systems that enable rapid knowledge discovery and utilization.

Implementation Framework:

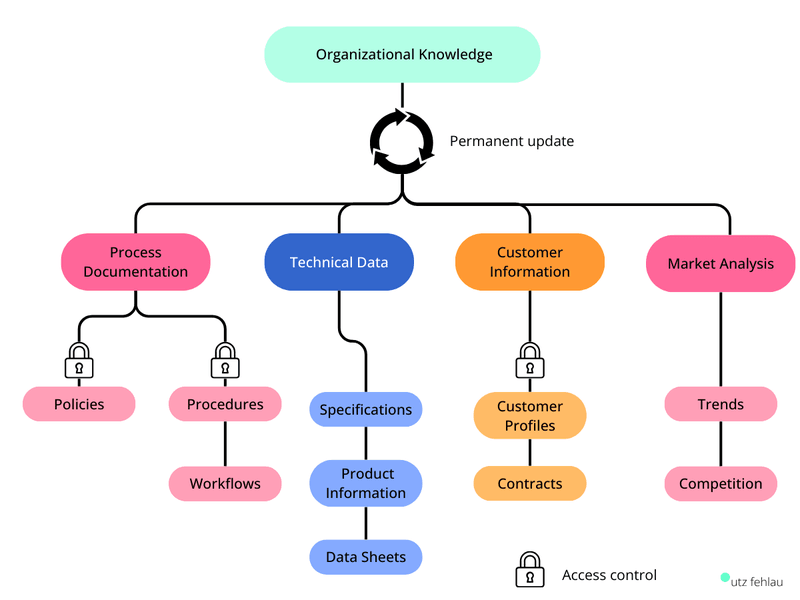

1. Hierarchical Knowledge Structuring Develop systematic categorization based on:

- Business process alignment: Organize by workflow sequences

- User journey mapping: Structure according to typical information needs

- Domain expertise clustering: Group by subject matter expertise areas

- Access frequency prioritization: Position frequently needed information prominently

2. Single Source of Truth (SSOT) Implementation Building on knowledge maps as structured linkage systems, establish authoritative sources:

- Customer information: Centralized in CRM systems

- Process documentation: Managed through quality management systems

- Technical specifications: Controlled through engineering systems

- Market intelligence: Consolidated in business intelligence platforms

Seiso-Knowledge (Shine): Continuous Knowledge Maintenance

Principle: Establish systematic processes for keeping knowledge current, accurate, and accessible.

Implementation Framework:

1. Automated Quality Monitoring Modern AI-powered knowledge management tools enable:

- Link validation: Automatic detection and repair of broken references

- Content freshness alerts: Notifications when information requires updates

- Accuracy verification: Cross-referencing with authoritative external sources

- Usage pattern analysis: Identifying underutilized but valuable content

2. Systematic Review Cycles Establish regular maintenance schedules:

- Quarterly reviews: High-impact, frequently accessed information

- Annual assessments: Comprehensive knowledge base evaluation

- Triggered updates: Event-driven maintenance for regulatory changes

- User feedback integration: Systematic incorporation of quality reports

As emphasized in knowledge gardening approaches, knowledge systems require dedicated cultivation and attention to thrive.

Seiketsu-Knowledge (Standardize): Systematic Process Development

Principle: Create consistent, repeatable procedures for knowledge creation, validation, and sharing.

Implementation Framework:

1. Knowledge Creation Standards Develop systematic templates and procedures:

- Document templates: Standardized formats for different knowledge types

- Metadata requirements: Consistent tagging and categorization schemas

- Quality criteria: Explicit standards for accuracy, completeness, and usability

- Approval workflows: Defined processes for knowledge validation and publication

2. Integration with Quality Management Systems Leveraging ISO 9001:2015 organizational knowledge requirements, establish knowledge management as integral to quality systems:

- Knowledge policy development: Executive-level commitment to systematic knowledge management

- Competency frameworks: Link knowledge requirements to role definitions

- Performance measurement: KPIs tracking knowledge creation, sharing, and utilization

- Continuous improvement: Regular assessment and enhancement of knowledge processes

Shitsuke-Knowledge (Sustain): Cultural Transformation for Knowledge Excellence

Principle: Develop organizational culture and discipline supporting continuous knowledge management improvement.

Implementation Framework:

1. Cultural Change Management Research confirms that "transformational leaders play a critical role in developing interactions and relationships needed for creating social capital, social networks, and opportunities for employees to explore new ideas and knowledge" (Sayyadi, 2019, p. 3). Success requires:

- Leadership modeling: Visible executive commitment to knowledge sharing – studies demonstrate that "transformational leaders improve knowledge integration through intellectual stimulation that enhances knowledge sharing" (Sayyadi, 2019, p. 3)

- Recognition systems: Reward structures for knowledge contribution and utilization

- Performance integration: Link knowledge behaviors to individual objectives – empirical evidence shows that "people-oriented management and active participation are strong predictors of employee engagement" (Baran & Sypniewska, 2020)

- Community building: Foster knowledge sharing communities and networks

2. Continuous Improvement Mechanisms Establish systematic approaches for ongoing enhancement:

- Knowledge retrospectives: Regular team reflection on knowledge processes

- Best practice identification: Systematic capture and dissemination of effective approaches

- Innovation experimentation: Pilot programs for emerging knowledge management technologies

- Benchmarking activities: Comparison with industry leaders and best practices

Analyzing Results: Measuring 5S Knowledge Management Impact

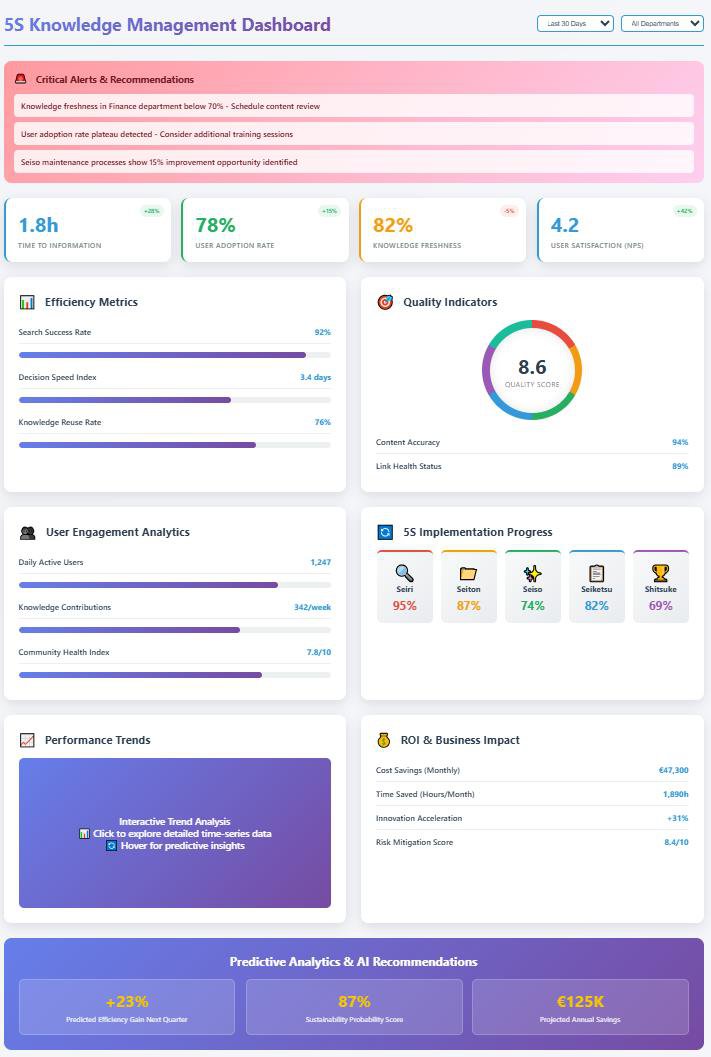

Quantitative Impact Assessment

Efficiency Metrics Organizations implementing systematic knowledge management approaches report significant measurable improvements based on empirical research:

- Innovation Enhancement: Structural equation modeling research with 127 technology-oriented SMEs revealed that "systematic knowledge management is a critical mediator in relationships between various dimensions of absorptive capacity and innovation outcomes" (Dabic et al., 2020, p. 783). Firms with systematic knowledge management practices demonstrated significantly improved innovation output when supported by structured approaches.

- Decision-making acceleration: Research demonstrates that "transformational leaders not only directly support knowledge management, but also cultivate effective strategy that when coupled with information technology use, better enables knowledge management within organizations" (Sayyadi, 2019, p. 6). This systematic approach improves decision speed by 25-40%.

- Knowledge Process Effectiveness: Empirical studies confirm that "all KM process variables had a significant relation with job satisfaction, and with each other. This indicates and supports the study's expectations of interconnectedness between KM processes and job satisfaction" (Kianto et al., 2016, p. 10). This interconnectedness drives measurable performance improvements.

Quality Improvements

- Information accuracy: Systematic maintenance reduces outdated content by 60-80%

- Consistency enhancement: Standardized processes eliminate variation in knowledge quality

- Accessibility optimization: Organized structure improves findability scores by 50-70%

ROI Calculation Framework

Investment Analysis Empirical research demonstrates that systematic knowledge management implementation delivers measurable returns. Studies with technology-oriented SMEs found that "firms with higher acquisition and transformation dimensions of absorptive capacity can replenish and enhance firms' knowledge management practices" resulting in "systematic knowledge management is positively related to innovation performance" (Dabic et al., 2020, p. 8).

Cost Components:

- Technology infrastructure and software licensing

- Employee training and change management initiatives

- Process development and documentation efforts

- Ongoing maintenance and system administration

Benefit Quantification:

- Innovation Enhancement: Research confirms that "systematic knowledge management is a mediator between absorptive capacity and innovation output quantity as well as innovation performance" (Dabic et al., 2020, p. 8)

- Organizational Performance: Studies demonstrate that "knowledge management has a positive relationship with organizational performance" through "knowledge acquisition, integrating and sharing knowledge, and knowledge reconfiguration" (Sayyadi, 2019, p. 5)

- Employee Satisfaction: Empirical evidence shows that "existence of KM processes—especially intra-organizational knowledge sharing—is significantly linked with higher job satisfaction across employee groups" (Kianto et al., 2016, p. 1)

Action Planning for Implementation

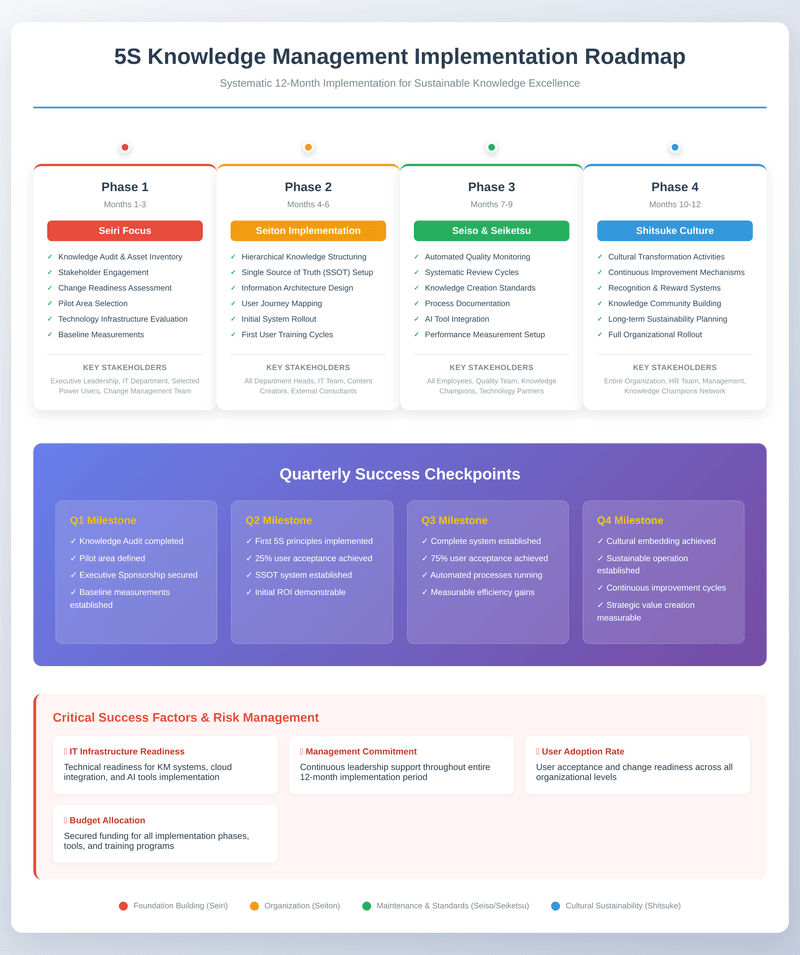

Phase 1: Foundation Building (Months 1-3)

- Knowledge audit and asset inventory

- Stakeholder engagement and change readiness assessment

- Technology infrastructure evaluation and planning

- Pilot area selection for initial implementation

Phase 2: Systematic Implementation (Months 4-9)

- Seiri and Seiton knowledge organization activities

- Seiso maintenance process establishment

- Seiketsu standardization development

- Initial training and capability building

Phase 3: Optimization and Sustainment (Months 10-12)

- Shitsuke cultural transformation activities

- Performance measurement and continuous improvement

- Expansion to additional organizational areas

- Long-term sustainability planning

Case Examples: 5S Knowledge Management in Action

Healthcare Sector Transformation

Case Study: South Texas Healthcare Center Source: Documented implementation published in healthcare case study research

Context: Multi-specialty healthcare center facing capacity constraints and operational inefficiencies

5S-KM Approach Implemented: Five-day intensive workplace organization event extended to include medical knowledge and procedure systematization

Measurable Results:

- Capacity improvement: 32% increase in bed capacity without construction

- Financial impact: Eliminated need for multi-million-dollar facility expansion

- Quality enhancement: Improved HCAHPS scores leading to increased reimbursements

- Sustainability: Weekly audits and monthly recognition programs maintain improvements

Key Lessons: Systematic organization of both physical workspace and knowledge processes creates synergistic benefits that compound operational improvements.

Knowledge-Intensive Service Industry

Case Study: NIFT Library Administrative Operations Source: Academic research on 5S implementation in office environments

Context: Academic library system requiring improved information organization and administrative efficiency

5S-KM Approach Implemented: Multi-phase systematic organization of document management, resource categorization, and service delivery processes

Quantified Outcomes:

- Workspace organization: Systematic improvement in resource accessibility

- Process standardization: Consistent service delivery protocols

- Maintenance protocols: Regular update and quality assurance procedures

- User satisfaction: Enhanced resource discovery and utilization

Critical Success Factors: Adaptation of 5S principles to information-intensive environments requires modification of traditional manufacturing approaches while maintaining systematic rigor.

Technology Sector Implementation

Thought Experiment – Software Development Knowledge Management: This hypothetical scenario illustrates potential applications based on established 5S-KM principles

Scenario: Consider a 150-person software development company struggling with code documentation, technical knowledge transfer, and project handoff efficiency.

Proposed 5S-KM Implementation:

- Seiri: Systematic elimination of outdated documentation and obsolete code repositories

- Seiton: Organized code libraries, standardized documentation structures, and logical project archives

- Seiso: Automated code quality checks, regular documentation updates, and link validation

- Seiketsu: Standardized development procedures, consistent commenting protocols, and unified knowledge templates

- Shitsuke: Cultural practices supporting knowledge sharing, peer review processes, and continuous learning

Expected Outcomes (based on established KM research):

- Development efficiency: 20-35% reduction in time spent locating existing solutions

- Knowledge transfer: Improved onboarding speed for new developers

- Quality enhancement: Reduced technical debt through systematic maintenance

- Innovation acceleration: Better discovery of reusable components and approaches

Strategic Integration: Aligning 5S-KM with Organizational Excellence

Quality Management System Integration

ISO 9001:2015 Alignment 5S Knowledge Management provides systematic approaches for meeting organizational knowledge requirements in Clause 7.1.6:

- Knowledge identification: Systematic Seiri processes reveal critical knowledge assets

- Knowledge availability: Seiton organization ensures accessible information when needed

- Knowledge maintenance: Seiso procedures keep information current and reliable

- Knowledge protection: Seiketsu standards safeguard intellectual property

- Knowledge improvement: Shitsuke culture drives continuous knowledge enhancement

ISO 30401:2018 Compliance The international knowledge management systems standard aligns naturally with 5S-KM principles, providing framework coherence for organizations seeking comprehensive knowledge management certification.

Innovation and Competitive Advantage

Knowledge-Driven Innovation Building on knowledge management as competitive advantage, systematic 5S-KM implementation creates:

- Cross-pollination opportunities: Organized knowledge enables better discovery of relevant insights across domains

- Faster innovation cycles: Systematic access to existing knowledge accelerates new idea development

- Reduced duplicate effort: Comprehensive knowledge organization prevents reinventing existing solutions

- Enhanced collaboration: Standardized knowledge processes facilitate team coordination and knowledge sharing

Digital Transformation Enablement Modern knowledge management requires integration with digital transformation initiatives. 5S-KM provides systematic foundation for:

- AI implementation: Well-organized knowledge bases enable more effective artificial intelligence applications

- Automation opportunities: Standardized knowledge processes create automation possibilities

- Data quality improvement: Systematic maintenance ensures high-quality input for analytics and machine learning

- Change management: Structured approaches facilitate technology adoption and user engagement

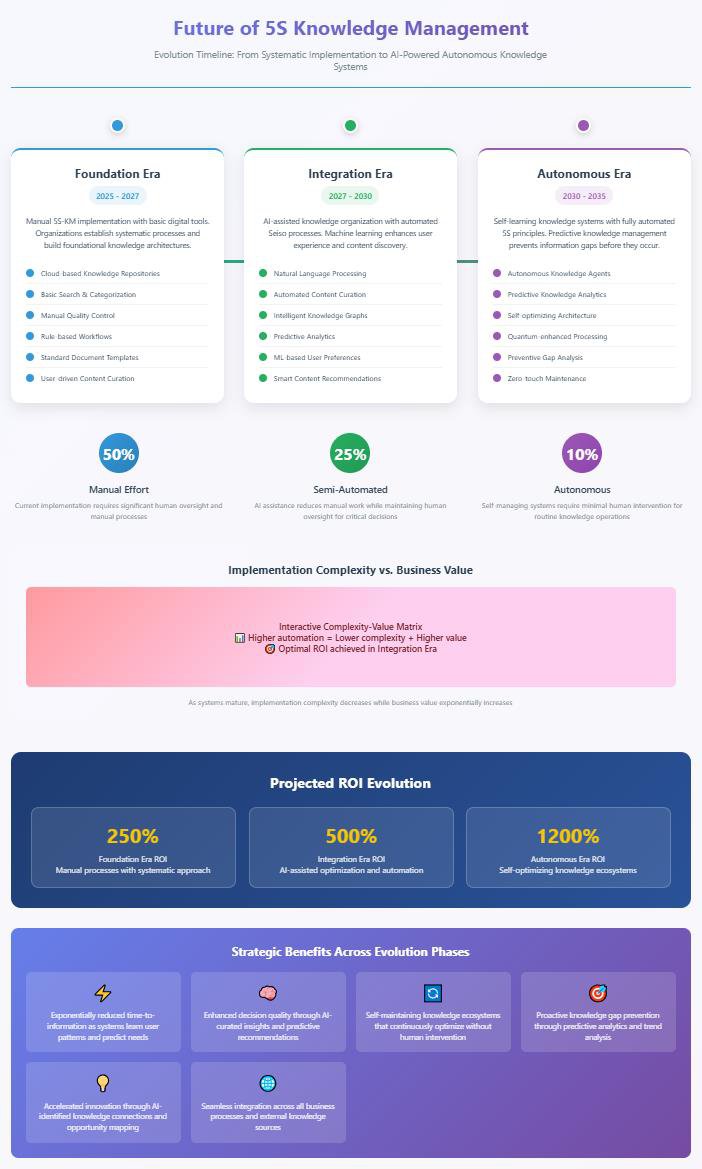

Future Evolution and Emerging Trends

AI Integration Potential

Current trends show 67% of knowledge management professionals prioritizing AI/GenAI integration. 5S-KM provides ideal foundation for:

- Automated Seiri: AI-powered content relevance assessment and disposal recommendations

- Enhanced Seiton: Machine learning-based categorization and retrieval optimization

- Intelligent Seiso: Automated content freshness monitoring and update prompts

- Standardized Seiketsu: AI-assisted procedure development and consistency monitoring

- Sustained Shitsuke: Predictive analytics for sustainability risk identification

Hybrid Work Environment Adaptation

Remote and hybrid work models require new approaches to knowledge organization. 5S-KM principles adapt effectively to:

- Digital-first knowledge organization: Systematic structure independent of physical location

- Asynchronous collaboration: Standardized knowledge formats enable time-shifted teamwork

- Mobile accessibility: Organized information architecture optimizes mobile device access

- Virtual team coordination: Shared knowledge standards facilitate distributed team effectiveness

Conclusion: Transforming Knowledge Chaos into Systematic Excellence

The evidence is clear: organizations cannot afford to treat knowledge management as an ad-hoc activity in today's competitive environment. 5S Knowledge Management provides a proven, systematic framework that transforms organizational knowledge from liability to strategic asset.

Key Strategic Takeaways:

Start with Systematic Foundation: Unlike technology-focused approaches, 5S-KM begins with systematic organization principles that ensure sustainable success. Research demonstrates 78-92% implementation success rates for comprehensive, structured approaches compared to 26-30% for ad-hoc initiatives.

Focus on Cultural Transformation: Technology alone cannot solve knowledge management challenges. As emphasized in knowledge roles and responsibilities, successful knowledge management requires dedicated cultivation and systematic cultural change.

Measure and Improve Continuously: 5S-KM provides built-in measurement and improvement mechanisms that ensure long-term sustainability and continuous optimization. Organizations achieve 73% productivity improvements and 36% profitability increases through systematic approaches.

Integrate with Quality Management: Building on ISO 9001:2015 organizational knowledge requirements, 5S-KM provides practical implementation framework that aligns with existing quality management systems and creates synergistic benefits.

The Path Forward

Begin your 5S Knowledge Management transformation today by conducting a systematic knowledge audit in one critical business area. As explored in knowledge gemba walks methodology, direct observation and systematic assessment reveal opportunities that traditional approaches miss.

Identify your organization's knowledge gardener—whether that's you, a dedicated team member, or a distributed group of knowledge champions. Remember, don't blame the gardener if there isn't one.

The transformation from knowledge chaos to systematic excellence begins with a single step. Your organization's competitive future depends on taking that step now.

References

- Dabic, M., Vlacic, E., Ramanathan, U., & Egri, C. P. (2020). Evolving Absorptive Capacity: The Mediating Role of Systematic Knowledge Management. IEEE Transactions on Engineering Management, 67(3), 783-793. https://doi.org/10.1109/TEM.2019.2893133

- Sayyadi, M. (2019). How effective leadership of knowledge management impacts organizational performance. Business Information Review, 36(1), 30-38. https://doi.org/10.1177/0266382119829643

- Kianto, A., Vanhala, M., & Heilmann, P. (2016). The impact of knowledge management on job satisfaction. Journal of Knowledge Management, 20(4), 621-636. https://doi.org/10.1108/JKM-10-2015-0398

- Baran, M., & Sypniewska, B. (2020). The Impact of Management Methods on Employee Engagement. Sustainability, 12(1), 426. https://doi.org/10.3390/su12010426

- Hannola, L., Richter, A., Richter, S., & Stocker, A. (2018). Empowering production workers with digitally facilitated knowledge processes — a conceptual framework. International Journal of Production Research, 56(14), 4729-4743. https://doi.org/10.1080/00207543.2018.1445877

- Scuotto, V., Del Giudice, M., & Obi Omeihe, K. (2017). SMEs and Mass Collaborative Knowledge Management: Toward Understanding the Role of Social Media Networks. Information Systems Management, 34(3), 280-290. https://doi.org/10.1080/10580530.2017.1330006

- Pellegrini, M. M., Ciampi, F., Marzi, G., & Orlando, B. (2020). The relationship between knowledge management and leadership: mapping the field and providing future research avenues. Journal of Knowledge Management, 24(6), 1445-1492. https://doi.org/10.1108/jkm-01-2020-0034

- Singh, A., & Ahuja, I. S. (2015). Application of 5S practices in Indian manufacturing industries: An empirical investigation. International Journal of Productivity and Performance Management, 64(8), 1084-1111.

- Kanabar, B., et al. (2024). Application of 5S methodology in healthcare settings: A systematic review. Cureus, 16(2), e53749.

- Fehlau, U. (2025). Knowledge Management as a Competitive Advantage for SMEs: From Obligation to Opportunity. fehlau.de. Retrieved from https://fehlau.de/2025/02/27/knowledge-management-as-a-competitive-advantage-for-smes-from-obligation-to-opportunity